1.Features

The machine can process precisely internal or external diameter, face, taper, arc and threading with high efficiency

Standard toolpost is 4-stations, also 6-stations toolpost can be optional selection

Spindle speed changed by frequency

Induction harden bed-way. Bed saddle with plastic sticker can improve the accuracy and service life of the machine

The spindle is surpported by imported precision bearings

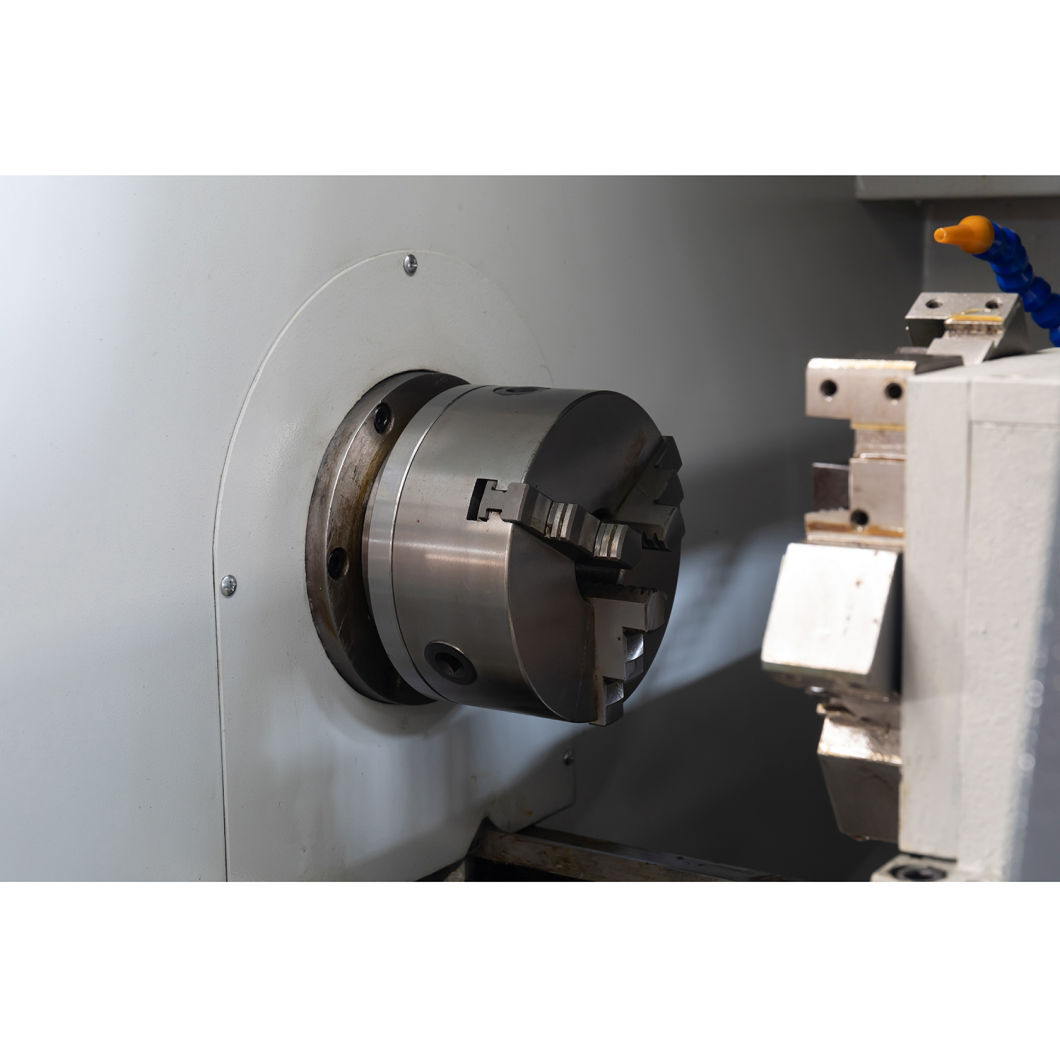

Normally machine is provided with 3-jaw chuck. According to customer's optional selection, hydraulic chuck or pneumatic chuck also can be supplied.

2.Specification

| Model and specification | CK6136/500/750/1000 |

| Swing over bed | φ1360mm |

| Swing over TOOLPOST | φ1180mm |

| Distance between centers | 500/750/1000mm |

| Max.machining length | 500/750/1000mm |

| Chuck size | φ160mm |

| Spindle nose and taper stype | A2-5 |

| Spindle speed range | 60-2500 |

| Spindle bore dia. | φ51 |

| Spindle power | 3 |

| Max.bar feeding dia | φ45 |

| Rapid traverse speed | 6/8 |

| Stations No. | 4/6 |

| X/Z Accurac of positioning repeatability | 0.01/0.02 |

| Quill diameter | φ50 |

| Quill travel | 120 |

| taper of quill | MT4 |

| Guideway width | 206 |

| Overall size | 1850*1100*1650mm 1900*1100*1650mm 2300*1100*1650mm |

| Net weight | 1450/1500/1600KG |

3.Standard Equipment

Cooling system

Auto-lubricating system

Light system

GSK-980TDc or Siemens 808D

4-Position electrical tool post

Iron casting machine stand

Manual 3-jaw chuck

Optional Accessories:

GSK, Siemens or other controller

6/8-Position electrical tool post

Hydraulic chuck

Bar Auto-feeding (KT-16 and KT-20)

4.Machine Photo

5.Factory photo

5.Factory photo